Contract Electronics Manufacturing (CEM)

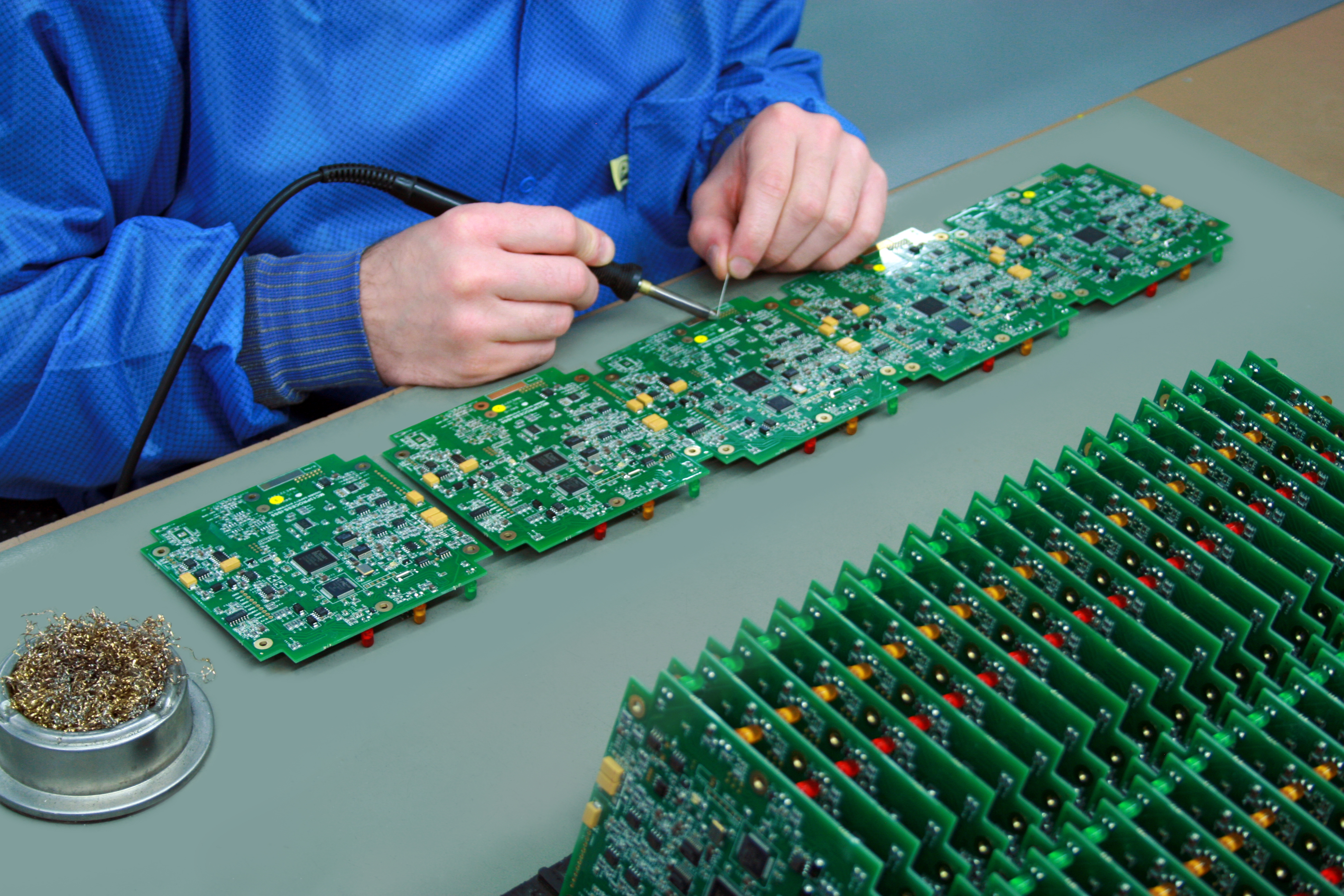

Hand and wave solder PCB assembly

The hand insertion and wave solder line is configured for optimum flexibility, allowing PCB assembly from 1-off quick turnaround prototype runs through low to medium volume production throughputs.

Our line consists of:

|

Hand Assembly, Unit Assembly and Test

Hand soldering is available for specialized or custom-build PCB assemblies. All our operatives are trained to IPC standards to ensure that quality is built in to the products. We have the facility to manufacture prototype to full batch cable assemblies and wiring harnesses to the customer’s specifications.

Our equipment consists of:

-

OKI Metcal Soldering Station: The MFR-1100 model offers SmartHeat® Technology to provide exceptional power for high thermal demand applications. Single or dual simultaneous outputs allow for single or dual hand-piece use.

-

JBC Soldering station:The CD-B is a soldering station with the JBC Advanced system for general electronic applications. The system recovers the tip’s temperature extremely quickly. This increases work efficiency and lowers the solder temperature. This innovative technology allows a reduction of the temperature by at least 50ºC.

- Ersa IR 500A BGA Rework Station: The IR 500A allows for safe and uniform rework without the need for component specific nozzles.

-

Weller multi -analogue rework stations: The advanced technology of Weller hot air stations ensures greater controlled precision when soldering and desoldering sensitive SMD components.

-

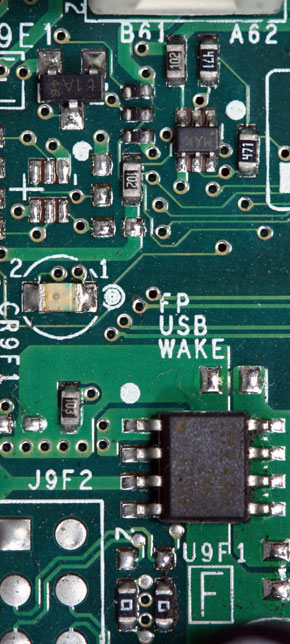

Mantis vision inspection: visual inspection microscope, providing truly superb magnification imaging with unparalleled freedom of head movement.

-

Circuit PCB VCut Depanelers/Separators: The Circut depaneler has been developed to separate/depanel v-cut scored, PCB assemblies cleanly and effortlessly to reduce distortion in the depaneling "breakout" process. This reduces scrap rates and "in the field" failures.

-

Hepco Radial Pre-former

-

OLAMEF Axial Pre-former

-

Planar Croppers

-

Carpenter-Compu-Strip 96: The Compu-Strip96 is a fully programmable bench top Measure, Cut & Strip Machine.

-

Cable Pressing Tools

-

OLAMEF component crimp tools

Copyright 2024 ABI Electronics Limited - Registered in England - No 1824588

Copyright 2024 ABI Electronics Limited - Registered in England - No 1824588